Where to use

Grip Stone can be used for interior and exterior purposes. It is a specialized product for roughening the unpolished surfaces of Marble, Granite or

any other natural stone / tiles before fitting for better grip.

It can be used on any size of Marble, Granite or any other natural stone / tiles. Once it is applied on Marble, Granite or any other natural stone /

tiles, after 24 hours, you can fit it with cement / or suitable product to any Concrete structures, render sand, all cementitious products, to new and

old cement plastered surfaces, to ceramic /porcelain tiles, concrete, brick, stone and marble surfaces even Tile over tile, marble over marble,

granite over granite…etc.

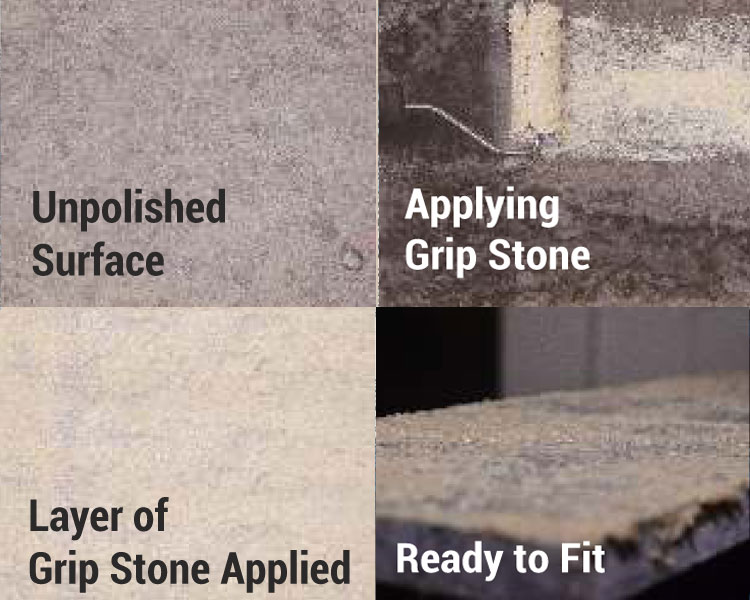

Surface Preparation

While fitting of Marble, Granite or any other natural stone / tiles we keep polished surface

out and fix unpolished surface with wall. So we have to apply Grip-Stone on unpolished

surface for better grip. The unpolished surface must be clean, free of oil, grease, wax, dust,

sand, dirt, laitance, paints etc.